Recent global events, even in the last week, have once again highlighted the vulnerabilities in the supply chain and their impact on prices.

We are seeing price increases across the board, driven by increases in energy and oil prices. Uncertainty in the world caused by current crises is likely to push up inflation further in the coming weeks and months.

The latest brent crude oil price is creeping above $100 per barrel, which will have knock-on effects of prices everywhere. This is off the back of economies reeling during Covid-19 pandemic lockdowns and still in the process of recovery.

So, in short, expect prices to be steadily rising over the coming weeks and months! It’s not good news, for anyone. So, what can organisations do in response? And specifically, what can strategic, efficient and effective procurement do to respond to increasing prices?

One of the tools in the procurement toolbox is Demand Management. Outside of re-procurement, re-tendering, price negotiations etc… there is a stage prior which is the utilisation of Demand Management principles and initiatives.

It’s not rocket science, and likely many people did this when there were shortages of toilet roll in the early days of the Covid-19 pandemic – they probably just didn’t know it was called ‘demand management’.

What is Demand Management?

Demand Management is a specific and targeted initiative to control costs by reducing demand at the user end, before we even consider going out to market, tendering, getting quotes etc… Put simply, it is the process of reducing need. It is about distinguishing between ‘wants’ and ‘needs’ before making a final procurement decision.

It is about influencing spend habits within an organisation to control spending so that you buy less.

Procurers have a few tools within Demand Management which can help.

The Make or Buy decision

- Do we need to buy this?

- Can we meet the need elsewhere within existing resources?

- Is it a critical/essential purchase or is it desirable?

The best way to save money and prevent price creep is simply to stop buying or not buy at all. The classic category where this can apply is ‘consultancy’ needs. Often organisations ‘buy in’ consultant support without fully realising that expertise can be ‘cobbled’ together in-house. Yes, that does mean diversion of resources, but are those resources being maximised anyway.

For large national organisations, it could be based around an equipment ‘re-use’ scheme, or ‘equipment loan scheme’, whereby instead of buying new IT equipment or office furniture, there is an internal ‘marketplace’ created where departments, teams, buildings can advertise unwanted assets for other departments, teams and buildings to ‘procure’ in order to reduce new spend.

It takes a little creativity, but think about what categories of spend could lend itself to this ‘make or buy’ decision.

The critical part is embedding a key ‘gateway’ stage to ask that make or buy question within your procurement policy and procedures and it needs to be policed.

Procurement Policy

Your procurement policy is the gateway for all procurements, regardless of value and risk. Procurers and budget holders across your organisation MUST follow policy and must be aware of what thresholds and processes are in place.

Failure to have a centralised procurement policy lends itself to ‘maverick’ spend which, at best results in duplication, loss of leverage, price increases and risks without formalised contract and at worst is an open door to fraud and corruption.

Specification Challenge and Management

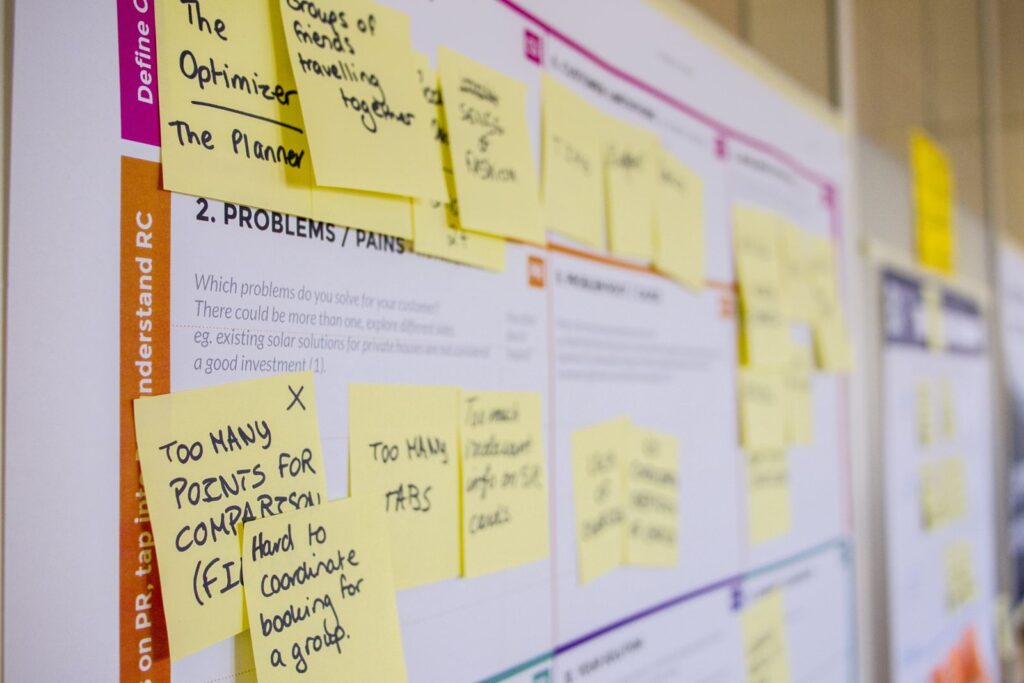

Professional procurers should be adept at challenging specifications. We may not be subject matter experts, but the first question I always ask is ‘how much of this is essential, how much of this is desirable’. If you MUST spend and procure, then challenge the specification.

Land on essential specification requirements first and then ask questions over everything else. Again the ‘Make or Buy’ question helps here as it may be that certain elements of your need can be sourced through a ’make’ in-house solution and you only need to procure part of the requirement.

Also, leverage supplier innovation and expertise. Even the most technically-minded of your organisation may not know what the latest supplier innovations are. Ask your suppliers what innovations could be leveraged to create efficiencies and reduce cost, and include it as a key requirement!

Communication, Communication, Communication

Demand management only works at an organisational level if all budget holders and procurers are understanding of the principle and are onboard with the importance of scrutinising need.

A good ‘strategic’ procurement function will have a communication strategy for disseminating procurement policy and strategy across an organisation.

If not, you need to get the word out and quickly with clear guidance on what spends (based on value threshold) need to be subject to a demand management challenge.

Plan Ahead

If you don’t have a forward procurement plan then this must become a strategic priority. A forward procurement plan is simply a list of your upcoming procurements over the coming year and beyond.

This is informed by your contracts register which should (if it’s a good one!) inform of when contracts are ending so you can judge when and how much time is needed to re-procure based on value, complexity and risk.

In the absence of a forward procurement plan I will guarantee that your procurement is reactive and you have no time to do it.

That leaves little time for the demand management challenge, little time to judge whether there is a make or buy option, little time to scrutinise and challenge your specification and what will happen is that you will go to your incumbent supplier and seek a contract renewal.

Naturally because global prices are increasing, they will up your price. And given that it is likely this all happens within the last couple of weeks of the contract and outside of a formal procurement process, this will be a huge clue to your incumbent supplier that they are the only supplier in the running and they hold all the leverage. A recipe for price increases!

If you are concerned about prices rising and the impact on your budgets and you need a strategic procurement overview then please do get in touch with us.

Continue reading

More Insights

Why Variable Energy Rates Could Be the Worst Decision Your Organisation Makes

If you’re on Variable Energy Rates, review your options now. Even if wholesale prices look stable today, geopolitical tensions, supply chain disruptions or seasonal demand can send them soaring overnight—especially in a world where unpredictable leaders can change the game in an instant. At 2buy2 Energy, we help organisations secure competitive fixed-term contracts or join our energy basket.

2buy2 Launches Inclusive Green Energy Basket for UK Organisations

Join 2buy2’s new green energy basket – open to all organisations with a commercial meter. One supplier, central billing and wholesale rates from Oct 2025.

Supplier Update: Procurement Act 2023 and Upcoming Regulations

Stay informed on the latest changes in UK public procurement. Learn about the Procurement Act 2023 and the upcoming Public Procurement Regulations 2024, impacting suppliers in the education and public sectors. Discover key updates, new requirements, and essential steps to prepare for October 2024.